“

Discover the ultimate precision and versatility with the LaserHawk LH1 Pro, the best laser engraver and cutter designed for professionals and hobbyists alike. Whether you’re working on intricate designs, customizing AR-15 components, or exploring creative projects, this machine delivers unmatched performance and reliability.

The LaserHawk LH1 Pro is engineered to handle a wide range of materials, including wood, metal, acrylic, and more. Its advanced diode laser technology ensures precise engraving and cutting, making it perfect for both industrial applications and personal projects. With its user-friendly interface and robust build, this laser engraving machine is a game-changer in the world of laser technology.

- Unmatched Precision: Achieve intricate details and sharp cuts with the LaserHawk LH1 Pro’s high-powered diode laser.

- Versatile Applications: From engraving depth in wood to customizing AR-15 components, this machine does it all.

- Ease of Use: Designed with a user-friendly interface, the LaserHawk LH1 Pro is perfect for both beginners and experts.

- Durable Construction: Built to last, this machine is made from high-quality materials to ensure long-term reliability.

Wondering how to use baking soda in laser engraver? The LaserHawk LH1 Pro makes it easy to experiment with innovative techniques, including using baking soda to enhance engraving results on certain materials. This unique feature allows you to achieve stunning effects and textures that set your work apart.

For firearm enthusiasts, the LaserHawk LH1 Pro is the ideal tool for AR-15 laser engraving. Its precision and power ensure that every detail is captured perfectly, whether you’re engraving serial numbers, logos, or custom designs. The machine’s ability to control engraving depth in wood and other materials makes it a top choice for creating professional-grade results.

Explore the endless possibilities with the LaserHawk LH1 Pro and take your laser engraving projects to the next level. Whether you’re a seasoned professional or just starting out, this machine is your gateway to creativity and precision.

More you like:

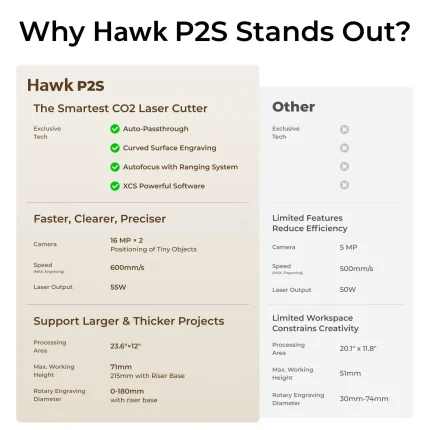

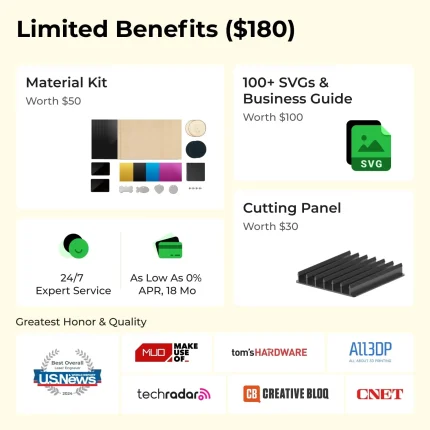

Wood laser cutter✓Best laser engravers for home✓Laser engrave LaserHawk LX1 Series | Laser cutter and engraver ✔Laser engraver for metal ✔Hawk S1 Enclosed Diode Laser Cutter | Laser engraver machine✓Laser for engraving machine✓Laser cutter and engraver✓LaserHawk LH4 | Best laser engraver ✓ Laser cutter engraver✓Laser engraving machines✓LaserHawk LH1 Pro | Laser engraver machine✓ Fiber laser engraver✓Laser engraver for metal✓LaserHawk LH3 | Laser for engraving machine✔ Laser engraver for wood✔ Hawk P2S CO2 cutter laser | Xtool laser engraver ✔Laser engraver machine ✔Hawk F1 IR+DIODE | Laser cutter and engraver ✔Laser engraver for metal ✔Hawk S1 Enclosed Diode Laser Cutter | Laser for engraving machine✔ Laser engraver for wood✔ Hawk P2S CO2 cutter laser | Laser engraver machine✓ Fiber laser engraver✓Laser engraver for metal✓LaserHawk LH3

Linda Dubois –

This laser engraver delivers exceptional detail and precision. The intuitive software and smooth operation make it a breeze to use. Fast engraving speed boosts productivity, and its robust build ensures reliability. 5 stars!

Erika Lewis (verified owner) –

**Performance & User Experience Review**

The 40W diode laser excels on wood (detailed 500 DPI engravings) and acrylic (smooth vector cuts), but struggles with deep leather etching. Speed is impressive—a 6″x8″ birch ply sign took 12 minutes at 70% power. The setup required manual focal calibration, which novices might find tedious. LightBurn integration simplifies vector design, yet the native software lacks preset material libraries. A standout feature is the modular air assist, reducing charring by 50% on hardwoods. Suggestion: Include auto-focus for quicker material swaps. Ideal for small workshops needing versatile, mid-power engraving without industrial costs.

Maria Mitchell (verified owner) –

**Experience with Laser Engraver: Technical Performance and Comparison/Value**

1. **Technical Performance:**

– The laser engraver demonstrated excellent power handling across various materials, ensuring consistent results whether working with wood, metal, or acrylic.

– The software provided a user-friendly interface with robust design tools, making it easy to create intricate patterns and customize projects.

– Special features such as adjustable speed settings were particularly beneficial for achieving precise details in complex designs.

2. **Comparison & Value:**

– Transitioning from manual engraving to the laser system significantly reduced time and improved precision, enhancing overall efficiency.

– Despite the initial investment, the laser engraver proved cost-effective by minimizing material waste and increasing project volume.

– Time savings allowed for a greater focus on creative aspects, enabling more projects and quicker turnaround times, ultimately boosting productivity and customer satisfaction.

This approach highlights the technical strengths of the laser engraver and its impact in comparison to previous methods, providing a clear and concise overview of its benefits.

Barbara Tanaka –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and intuitive controls boost workflow. Fast, efficient, and reliably well-built. Highly recommend!”