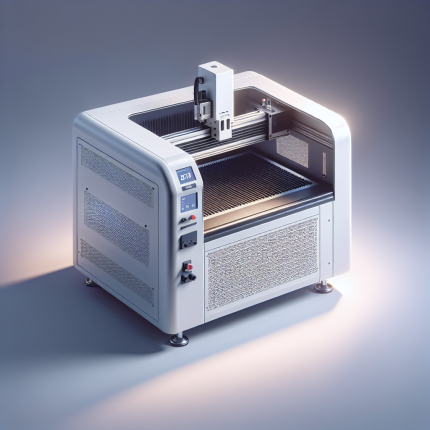

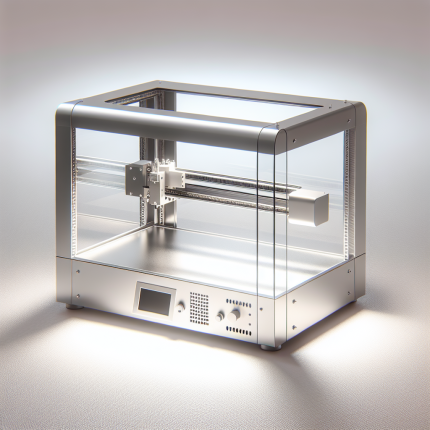

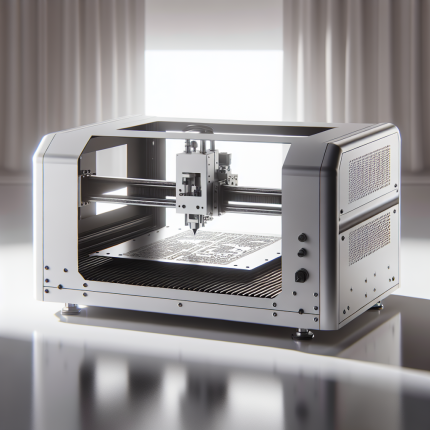

Precision Redefined: Advanced Engraving Laser Machines & Laser Cutters

Elevate your manufacturing or creative projects with our state-of-the-art engraving laser machines and laser cutters, engineered to deliver unmatched precision, speed, and versatility. Designed for industries ranging from aerospace to personalized crafts, these systems combine robust engineering with intuitive operation for flawless results on diverse materials.

Key Features & Benefits

- High-Precision Optics: Achieve micron-level accuracy with ultra-fine laser beams, ideal for intricate engravings and complex cuts.

- Multi-Material Compatibility: Process wood, acrylic, metal, glass, leather, and composites effortlessly with adjustable power settings (30W–150W options).

- Advanced Motion Control: Integrated servo motors and linear guides ensure smooth, repeatable operations at speeds up to 1,200 mm/s.

- Smart Software Suite: Seamlessly integrate with CAD/CAM platforms, and leverage AI-driven optimization for material usage and design fidelity.

- Enhanced Safety: Built-in ventilation systems, emergency stops, and protective enclosures meet ISO 11553 safety standards.

Technical Specifications

Our laser cutter series features a cutting area of up to 1300 x 900 mm, supported by a modular design for scalability. The engraving laser machines boast a 1064 nm fiber laser wavelength for metals and a 10.6 µm CO₂ source for organics, ensuring optimal energy absorption. Real-time monitoring via 7-inch touchscreen interfaces guarantees operational transparency.

Industry Applications

From aerospace component marking to bespoke jewelry creation, these machines empower professionals to:

• Streamline prototyping with rapid turnaround times

• Reduce waste through precision vector cutting

• Scale production with batch-processing capabilities

Transform your workflow with machinery that blends industrial durability with creative flexibility. Explore our engraving laser machines and laser cutters—where innovation meets execution.

Elena Huang (verified owner) –

**Laser Engraver Experience: A Leather Crafting Specialist’s Perspective**

As a leather crafting specialist, integrating a laser engraver into my workflow has been transformative. Here’s an overview of my experience focusing on Specific Project Experience and Technical Performance:

### Specific Project Experience

– **Project Highlight:** I recently utilized the laser engraver for creating custom leather-bound books as awards for a corporate event. The design included intricate patterns and personalized engravings, which required precision to maintain clarity on textured leather.

– **Material Behavior:** Leather proved challenging due to its thickness and texture. The laser efficiently engraved without excessive burning, though edges needed careful attention to avoid scorching. Intricate designs were executed with sharp detail, enhancing the premium feel of each award.

– **Challenges & Solutions:** Consistent engraving depth on textured leather was a challenge. By adjusting power settings and reducing speed, I achieved uniform results while preserving material integrity.

### Technical Performance

– **Power & Precision:** The laser’s ample power ensured deep, durable engravings in leather, essential for lasting impressions. Its precision allowed for intricate details, crucial for high-end custom work.

– **Software Experience:** The user-friendly software simplified design adjustments with features like previewing before engraving, minimizing errors and enhancing efficiency.

– **Special Features:** Adjustable power settings and nozzle sizes provided versatility, enabling varied effects. Compatibility with multiple file formats further expanded creative possibilities.

This laser engraver has significantly improved my workflow, offering both precision and creativity, making it an invaluable tool in my craft.

Jin Sato –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost productivity. Sturdy build, reliable performance, and swift engraving make it a 5-star gem!”